G LAB

The Galvalux laboratories for testing and quality control, research and development, electroplating, coating and colour R&D, provide its production departments with all the assistance they need.

They are also equipped to certify the quality and development of their clients’ projects.

Main tests carried out

- Cross-cut test ISO 2409

- Salt mist ISO 9227

- Damp heat ISO 4611

- Synthetic sweat EN 1811

- Thioacetamide corrosion test ISO 4538

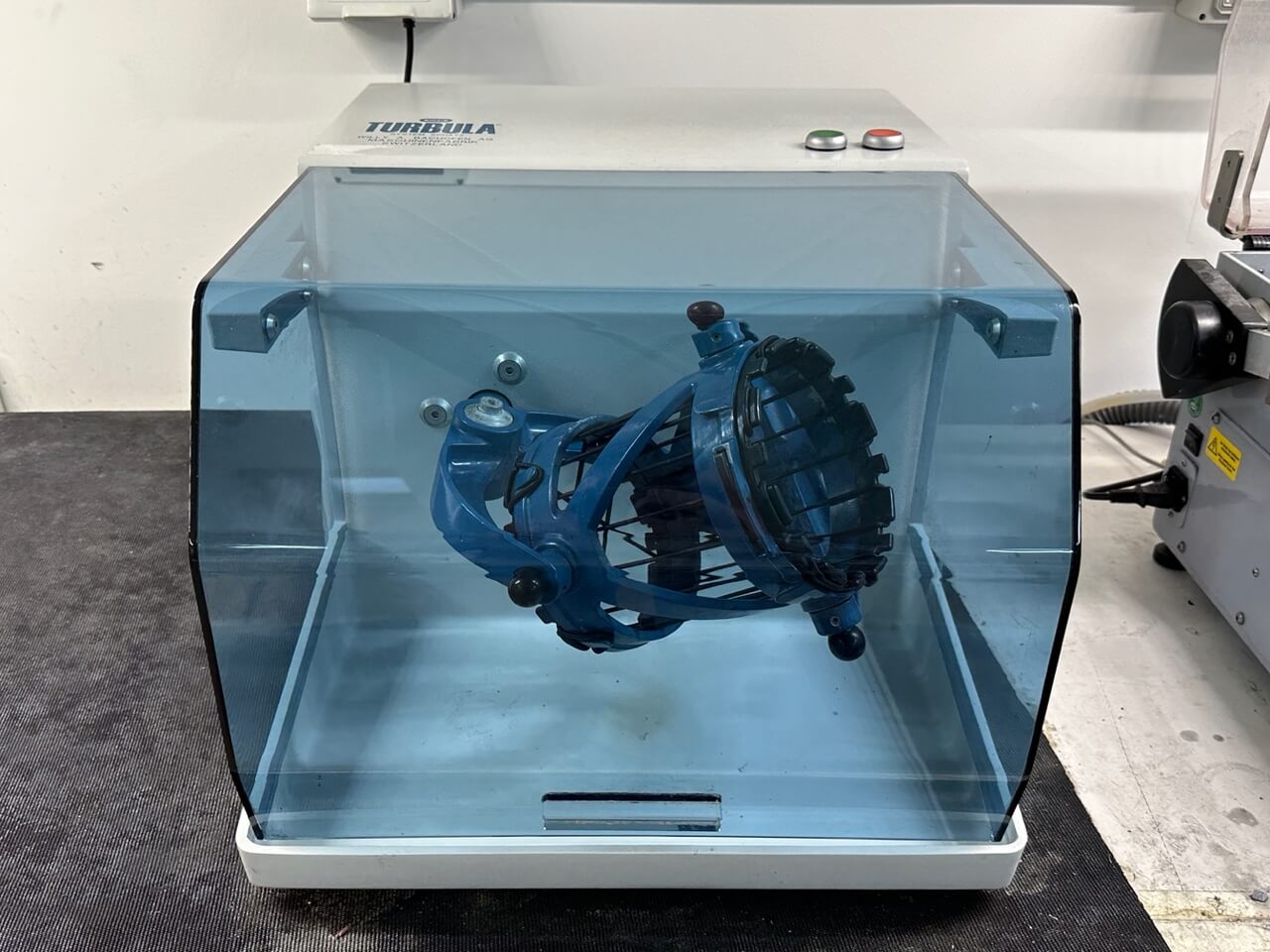

- “Turbula” wear test (internal test) 30′

- Xenotest ISO 105 B02 24h

- Dry cleaning (internal test)

- Domestic washing (internal test)

- Boiling (internal test)

- Free fall resistance (internal test)

- Other specific tests upon request (pencil hardness test, other specific wear tests, etc.)

- POLISERVICE

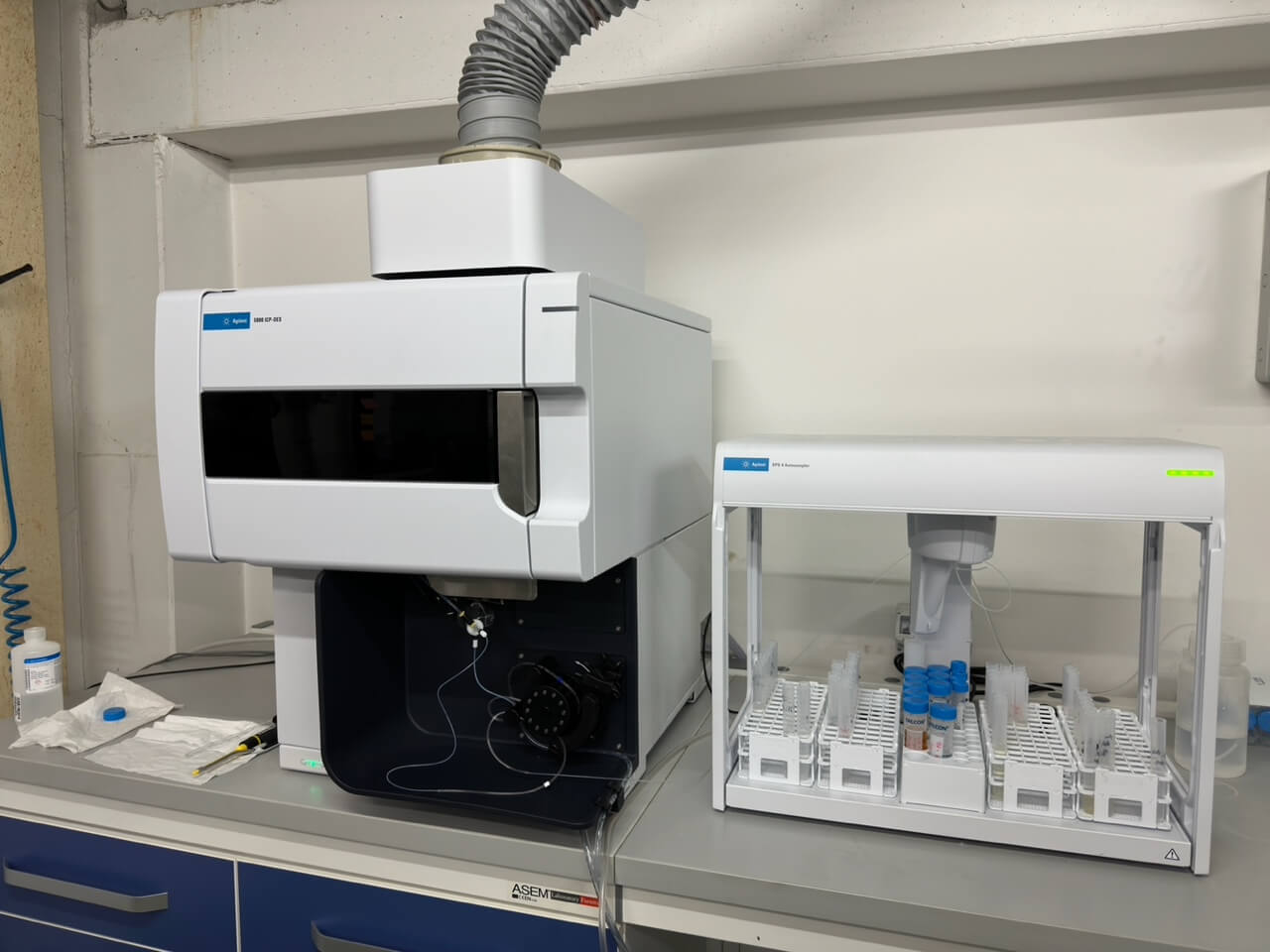

Main equipment used:

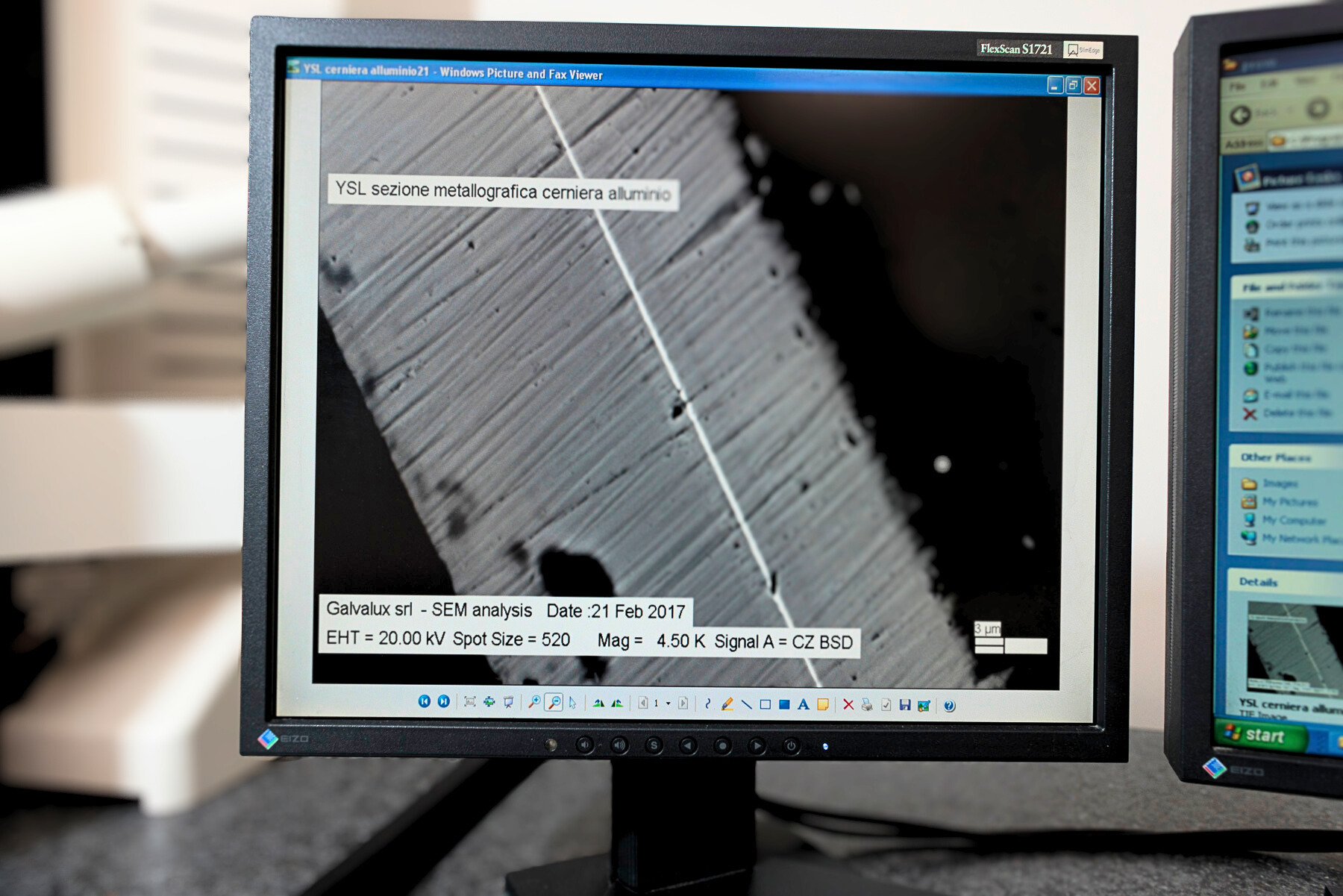

- SEM/EDX

- SPECTROPHOTOMETER

- SALT MIST CHAMBER

- POTENTIOSTAT/GALVANOSTAT

- CABIN FOR XENOTEST

- FTIR SPECTROMETER

- CLIMATE CHAMBER

- XRF SPECTROMETER

- HPLC